Applications

Agricultural equipment: tractors, combine harvesters, crop sprayers, bulldozers, graders, etc;

Automotive industry: power steering pumps, steering gear thrust washer, disc brakes, shock absorbers, door hinges, wiper, recliner chairs, air valve and solenoid valve;

Business office equipment: copiers, fax machines, printers, mail processor and the like;

Hydraulic components and valves: gear pumps, piston pumps, vane pumps, ball valves, butterfly valves, cylinders, fuel tanks and other hydraulic components, etc;

Household appliances: refrigerators, air conditioners, vacuum cleaners, sewing machines, washing machines, microwave ovens and fitness equipment;

And other logistics machinery, packaging machinery, textile machinery, port machinery, mining machinery, forest machinery and all kinds of construction machinery and equipment.

FZ Retainer BearingFZ Retainer BearingRetainer bearing made copper alloy, hard alloy and POM colophony as holding frame, the surface was processed some well-regulated holes, and embed the rolling steel balls in the holes, orifice used technics of oil groove circle locked ball.

FZ Retainer BearingFZ Retainer BearingRetainer bearing made copper alloy, hard alloy and POM colophony as holding frame, the surface was processed some well-regulated holes, and embed the rolling steel balls in the holes, orifice used technics of oil groove circle locked ball. SF-1 Self-lubricating BearingSF-1 Self-lubricating BearingSF-1 self-lubricating metal composite materials to high-quality low-carbon steel substrate, sintered porous spherical copper powder layer, the surface rolled to the PTFE-based material as a wear-resistant lubricating the bearing layer.

SF-1 Self-lubricating BearingSF-1 Self-lubricating BearingSF-1 self-lubricating metal composite materials to high-quality low-carbon steel substrate, sintered porous spherical copper powder layer, the surface rolled to the PTFE-based material as a wear-resistant lubricating the bearing layer. JF-800 Bimetallic BearingJF-800 Bimetallic BearingJF-800/720/700/20/930 Bimetallic self-lubricating bearing used high quality low-carbon steel plate as base, sintered porous bronze as its surface, suitable for rotatory oscillating, reciprocating movements on the conditions of high load.

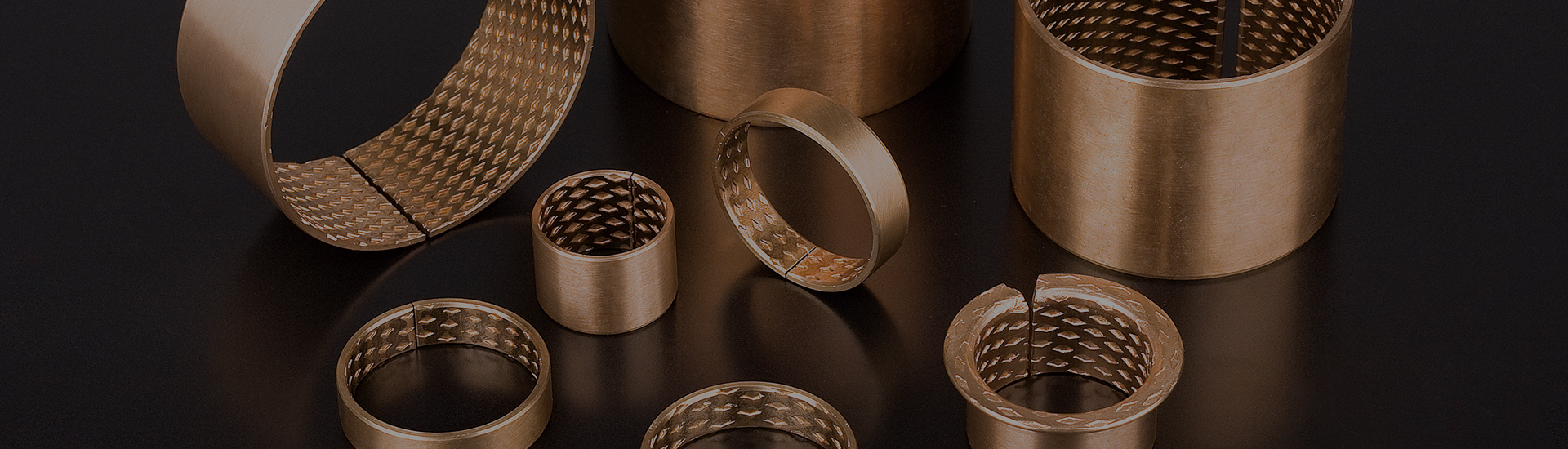

JF-800 Bimetallic BearingJF-800 Bimetallic BearingJF-800/720/700/20/930 Bimetallic self-lubricating bearing used high quality low-carbon steel plate as base, sintered porous bronze as its surface, suitable for rotatory oscillating, reciprocating movements on the conditions of high load. FB090 Bronze BearingFB090 Bronze BearingFB090 Bronze wrapped bushing, specially formulated high-density copper alloy strip base body surface may be requested by the user or hemispherical rolling diamond oil hole, oil sump.

FB090 Bronze BearingFB090 Bronze BearingFB090 Bronze wrapped bushing, specially formulated high-density copper alloy strip base body surface may be requested by the user or hemispherical rolling diamond oil hole, oil sump. JDB Solid-lubricant BearingJDB Solid-lubricant BearingJDB Solid- lubricant inlaid bearing use high grade metal alloys as their base material, inlaid graphite and grease during the process of friction, it will release solidlubricant and lubricant oil automatically.

JDB Solid-lubricant BearingJDB Solid-lubricant BearingJDB Solid- lubricant inlaid bearing use high grade metal alloys as their base material, inlaid graphite and grease during the process of friction, it will release solidlubricant and lubricant oil automatically.