1. Flexible design, simple and convenient, using a wide range;

Oil supply system in the mechanical design is a lot of work, time-consuming device, the use of solid self-lubricating bearings need not be considered in the design of fuel means saving fuel plant equipment, and can for a variety of special occasions, the solid self-lubricating bearings designed into a variety of shapes to meet the needs of a variety of special occasions, the use of solid self-lubricating bearings, can significantly reduce the mechanical maintenance, fuel and other expenses.

2. No oil can be used;

Since the coefficient of linear expansion of solid self lubricant is greater than the metal substrate, so when solid self-lubricating bearings start running, the film will be transferred to the upper grinding member achieved self-lubricating, so solid self-lubricating bearings can be used in difficult to refuel and can not refuel or fat place, even in the case of low speed, high load, but also can play a good lubrication.

3. Low cost;

Traditional mechanical design, operating within a certain time, to regular refueling and maintenance, check the fuel gauge, oil installations is smooth, due to regularly refuel the body itself and cause pollution of the surrounding environment, resulting in increase of the maintenance costs and achieve after self-lubricating, not only can make the environment clean, but also greatly reduces the cost of the use of lubricants. |

4. The high-load, low-speed conditions, can play a superior performance;

Solid self-lubricating bearings are used centrifugal casting high-strength brass alloy as a matrix, play a role in carrying the load, graphite has good self-lubricating properties of specially formulated as a lubricant, play a role in self-lubricating, it combines them the respective merits, even under high load, low speed conditions, can play a superior performance.

5. The reciprocating motion, rocking motion, start-stop and frequent film formation difficult place to play excellent wear resistance;

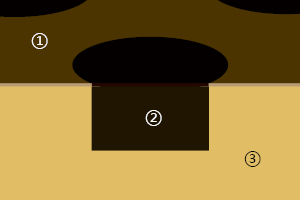

Solid lubricants self-lubricating bearing arrangement principle is to ensure that all parts of the grinding member has a lubricant effect during operation of the thus arranged with the lubricant must be based on the direction of movement of the grinding member arranged to determine the position of the lubricant.

6. superior chemical resistance and corrosion resistance;

Solid self-lubricating bearing lubricant is specially formulated with graphite, PTFE, molybdenum disulfide and other wear-resistant material, which has a stable molecular structure, metal matrix can have different chemical resistance and corrosion resistance depending on the metal of selected, solid self-lubricating bearings and therefore has excellent chemical resistance and corrosion resistance.

|

FZ Retainer BearingFZ Retainer BearingRetainer bearing made copper alloy, hard alloy and POM colophony as holding frame, the surface was processed some well-regulated holes, and embed the rolling steel balls in the holes, orifice used technics of oil groove circle locked ball.

FZ Retainer BearingFZ Retainer BearingRetainer bearing made copper alloy, hard alloy and POM colophony as holding frame, the surface was processed some well-regulated holes, and embed the rolling steel balls in the holes, orifice used technics of oil groove circle locked ball. SF-1 Self-lubricating BearingSF-1 Self-lubricating BearingSF-1 self-lubricating metal composite materials to high-quality low-carbon steel substrate, sintered porous spherical copper powder layer, the surface rolled to the PTFE-based material as a wear-resistant lubricating the bearing layer.

SF-1 Self-lubricating BearingSF-1 Self-lubricating BearingSF-1 self-lubricating metal composite materials to high-quality low-carbon steel substrate, sintered porous spherical copper powder layer, the surface rolled to the PTFE-based material as a wear-resistant lubricating the bearing layer. JF-800 Bimetallic BearingJF-800 Bimetallic BearingJF-800/720/700/20/930 Bimetallic self-lubricating bearing used high quality low-carbon steel plate as base, sintered porous bronze as its surface, suitable for rotatory oscillating, reciprocating movements on the conditions of high load.

JF-800 Bimetallic BearingJF-800 Bimetallic BearingJF-800/720/700/20/930 Bimetallic self-lubricating bearing used high quality low-carbon steel plate as base, sintered porous bronze as its surface, suitable for rotatory oscillating, reciprocating movements on the conditions of high load. FB090 Bronze BearingFB090 Bronze BearingFB090 Bronze wrapped bushing, specially formulated high-density copper alloy strip base body surface may be requested by the user or hemispherical rolling diamond oil hole, oil sump.

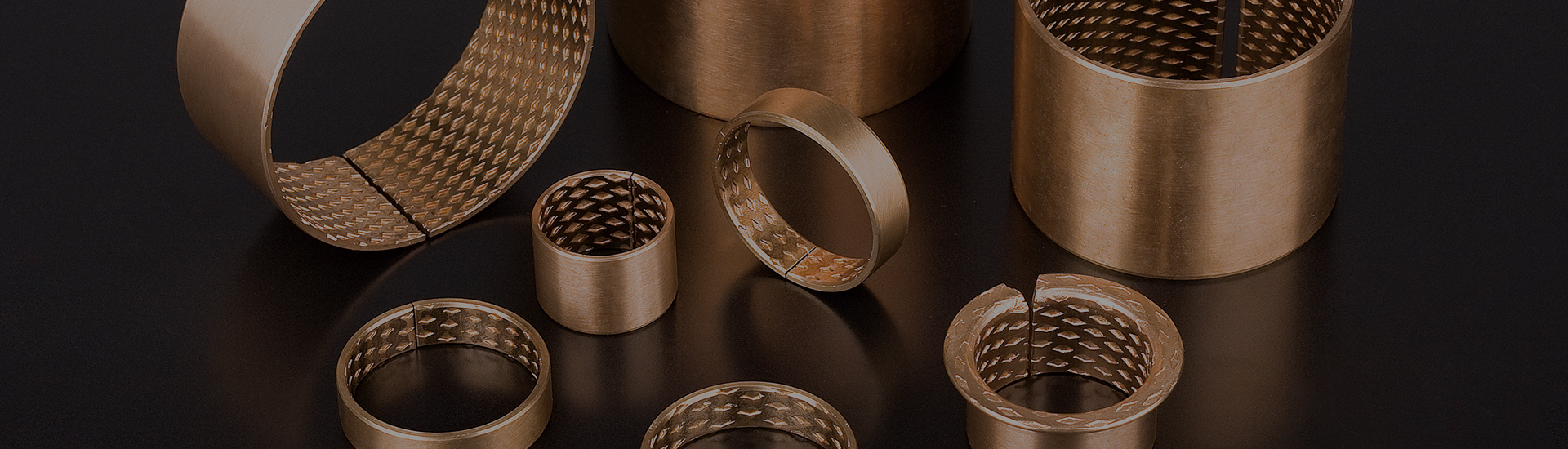

FB090 Bronze BearingFB090 Bronze BearingFB090 Bronze wrapped bushing, specially formulated high-density copper alloy strip base body surface may be requested by the user or hemispherical rolling diamond oil hole, oil sump. JDB Solid-lubricant BearingJDB Solid-lubricant BearingJDB Solid- lubricant inlaid bearing use high grade metal alloys as their base material, inlaid graphite and grease during the process of friction, it will release solidlubricant and lubricant oil automatically.

JDB Solid-lubricant BearingJDB Solid-lubricant BearingJDB Solid- lubricant inlaid bearing use high grade metal alloys as their base material, inlaid graphite and grease during the process of friction, it will release solidlubricant and lubricant oil automatically.